What We Mean by “Dehydrate”

Here at Easy Food Dehydrating, “dehydrate” always means using an electric food dehydrator — the easy, reliable way to dry food at home.

- Home

- How to Store Dehydrated Food for Long-Term Freshness

- Oxygen Absorbers for Dehydrated Food

Why Oxygen Absorbers for Dehydrated Food are a Must

If you’ve ever wondered how to keep your dehydrated foods fresh for years instead of months, the secret is simple: use oxygen absorbers. These little packets may look unassuming, but they lock in long-term freshness, protect against mold and bugs, and help you build a reliable food storage pantry.

✅ Quick Answer: What are oxygen absorbers for dehydrated food?

Oxygen absorbers are small, food-safe packets filled with iron powder that remove oxygen from sealed containers. By eliminating oxygen, they prevent mold, bugs, and rancidity, extending the shelf life of dehydrated foods like grains, beans, jerky, and dried fruits for years.

Think of oxygen absorbers as your food’s insurance policy — once you learn how to use them, you’ll never store dried foods without them again.

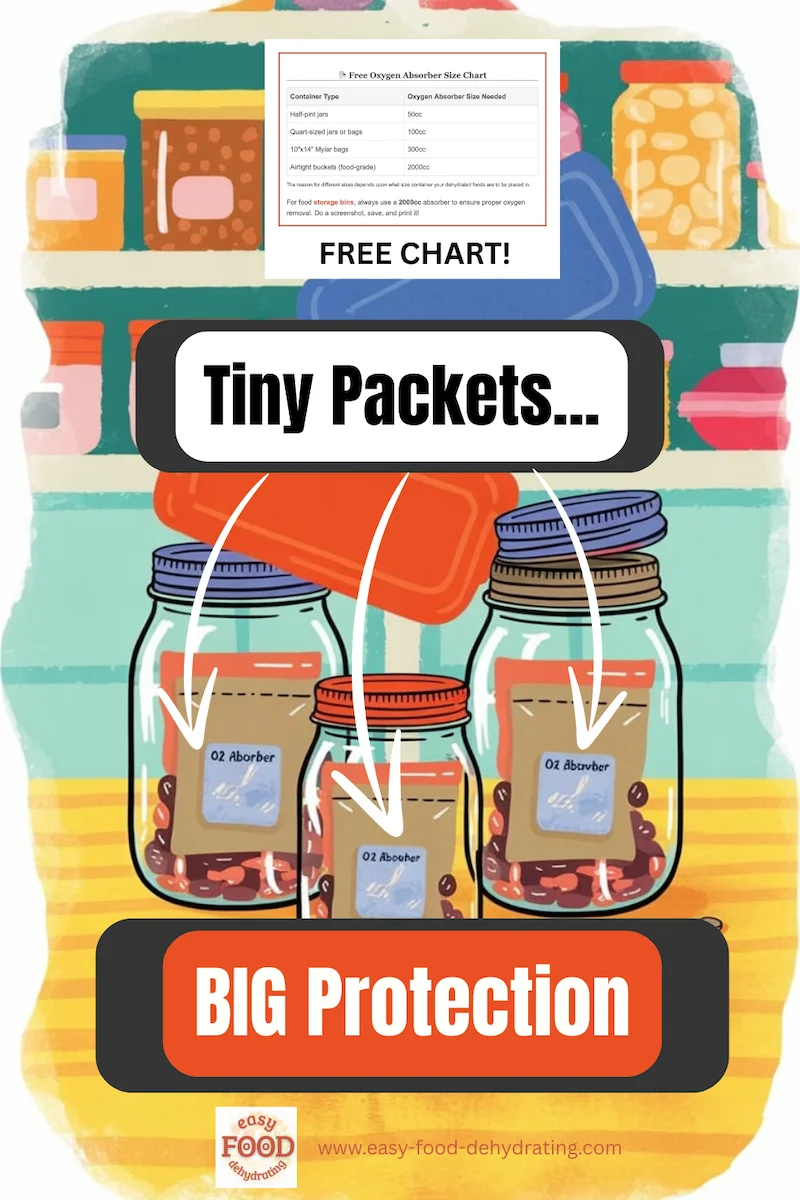

Please, scroll down for my free oxygen absorber SIZE chart!

★★★★★★

The page you are reading now is

ONE of the most IMPORTANT

pages on Easy Food Dehydrating

The page you

are reading now

is ONE of the most

IMPORTANT

pages on

Easy Food

Dehydrating

★★★★★★

Why is that? Well, if you're interested in storing food for the long term, make sure to add desiccant packets inside your dehydrated vacuum-sealer bags BEFORE sealing them with your FoodSaver machine or (whichever brand of vacuum-sealer you have).

📄 Free Oxygen Absorber Size Chart

| Container Type | Oxygen Absorber Size Needed |

|---|---|

| Half-pint jars | 50cc |

| Quart-sized jars or bags | 100cc |

| 10"x14" Mylar bags | 300cc |

| Airtight buckets (food-grade) | 2000cc |

For food storage bins, use a 2000cc absorber. Screenshot, save, or print for quick reference.

What’s Really Inside an Oxygen Absorber (and Why It Saves Your Food)

Oxygen absorbers are made of iron powder combined with salt. When exposed to oxygen, the iron oxidizes, effectively removing oxygen from the enclosed space. They are necessary for the following reasons:

- Slow oxidation - Oxygen accelerates food spoilage. Removing oxygen drastically slows rancidity, mold growth, and insect infestations.

- Moisture regulation - Iron oxidizing creates a small amount of heat that helps remove moisture condensation, keeping food crisp. Less moisture also inhibits mold as stated in #1.

- Storage life extension - With both oxygen and moisture minimized by our oxygen absorbers, the shelf life of sealed dried foods like grains, beans, nuts, and snack items is extended several years longer than without.

While air-tight containers alone help, adding oxygen absorbers provides an extra level of protection by actively targeting the main causes of food deterioration: oxygen and moisture.

Why Oxygen Absorbers Are the Lifeline of Long-Term Food Storage

Remember: Tuck a 100cc oxygen absorber inside the food vacuum bag JUST BEFORE you vacuum seal it, or drop an oxygen absorber in the Mason jar just before screwing on its lid.

If you're using a small (half-pint) Mason jar, use a 50cc oxygen absorber.

For quart-sized Mason jars, use a 100cc oxygen absorber.

Don’t Skip This Step: The #1 Reason Oxygen Absorbers Protect Your Food

The Oxygen Absorbers protect our dried foods by removing oxygen, and help deter insect damage. Using them extends the shelf life of our dried food by preventing mold growth, eliminating the need for commercial additives such as BHA, BHT, Sorbates, etc.

The oxygen absorber packets are non-toxic - which is good to know - as they are in direct contact with our dried foods!

Where to Buy Oxygen Absorbers (and How to Spot Fresh Ones)

When to Use 50cc Oxygen Absorbers

50cc are perfect for small jars and containers. Ideal for keeping spices and smaller dried foods fresh.

Best Uses for 100cc Oxygen Absorbers

100cc are great for quart-sized jars and vacuum-sealer bags. The most versatile size for everyday use.

- PackFreshUSA Oxygen Absorbers

- 200-Pack

- Food-Grade, Non-Toxic

- Oxy-Sorb Oxygen Absorbers

- 100-Pack

- Long-Term Food Storage Freshness Protection

- Oxy-Sorb Oxygen Absorbers

- Bags of 20 (60 Count total)

- Super Effective for Dried Goods

- Oxy-Sorb Oxygen Absorbers

- Pack of 10

- I use these for airtight bins and buckets

As an Amazon Associate, I earn from qualifying purchases — this does not affect the price you pay. Read full disclosure.

Pink Pill = GOOD

Blue/Purple Pill = BAD!

When the 100-pack of oxygen absorbers arrives, BEFORE OPENING IT

or putting it away, immediately check for the little pill in the

bag.

It MUST BE PINK. If it's BLUE/PURPLE... that's not good.

• • • • •

The pill turns BLUE/PURPLE when the pill has absorbed oxygen, therefore telling you that the contents of the shipment are probably no good.

So before you OPEN that shipped package, check for a pink pill.

If it's blue/purple, return that order unopened for a replacement!

Blue/Purple Pill =

NO GOOD!

The photo shows the pills that have turned from a very definite pink to an almost blueish-purple color.

This indicates that the oxygen absorbers contained in the bag are highly likely "no good."

Pro Tip: The Right Way to Store Bulk Oxygen Absorbers Without Wasting Them

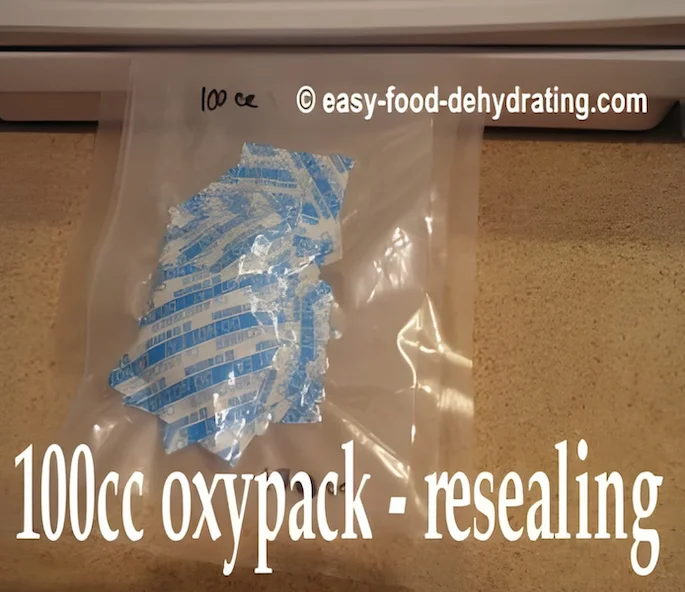

If the pill is good i.e. "pink," I'll open the new 100-pack bag and take out 5 brand new quart-size vacuum-sealer bags.

I then place 20 oxygen absorbers from the 100-pack bag

into each of the quart-size vacuum-sealer bags and immediately vacuum seal

them all.

The reason for splitting them up is we don’t want to open and seal the original big bag over and over just to take out one or two oxygen absorbers. Doing that would soon ruin all the other oxygen absorbers (by air infiltration) before we even get a chance to use them!

This means I now have FIVE quart-size bags with 20 oxygen absorbers in each of them.

The pink pill from the original bag can go into one of the five bags—no need to throw it away, we can reuse it until it turns purple!

Step-by-Step: How to Open and Reseal Oxygen Absorber Bags Without Ruining Them

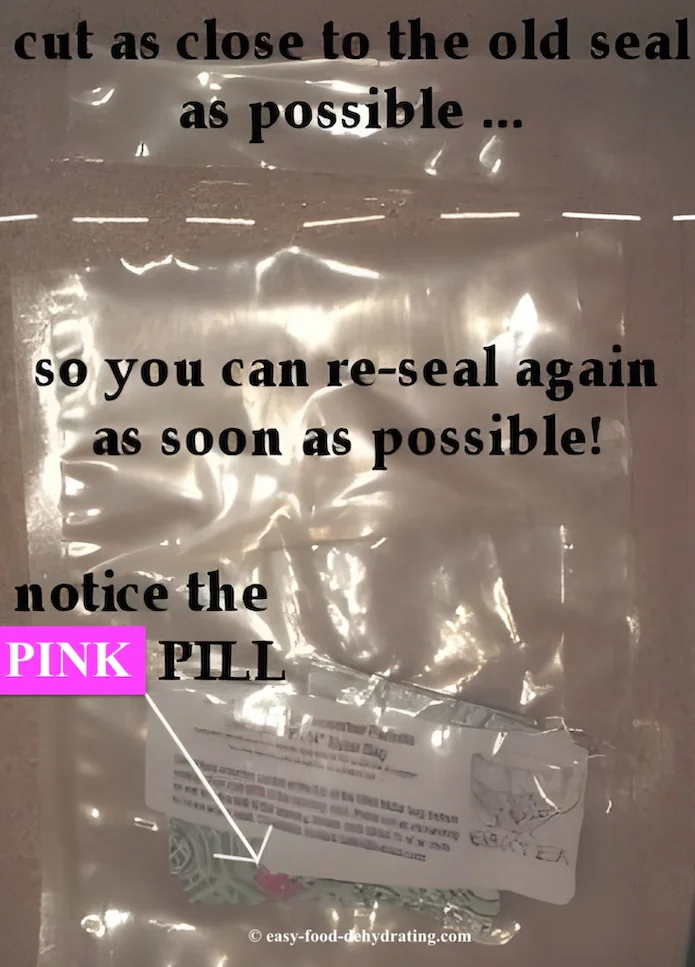

When I'm ready to use an oxygen absorber, I simply cut directly beneath the old seal at the top of the bag (shown as a dashed line at the top of the bag in the photo above).

Cut as straight as you can and as

close to the old seal as you can—then I remove as many packets as I

need and put them in the dehydrated food bags that are waiting to be

vacuum sealed. Then reseal that package.

Because you're cutting off the top seal each time and then resealing at the top again, you will be moving farther down the bag, if you will. What I'm prattling on about is if you just just cut the bag willy-nilly, you're wasting the bag and resealing possibility. Heck, if there's a long way of describing an easy step, I'll find it! LOL

When that resealing job is done, you're good to carry on with vacuuming your dehydrated food goodies. Don't forget to add the dang oxygen absorber in the bag before vacuuming... (Yep, it happens).

Reseal Opened Oxygen Absorber Bags ASAP

Re-vacuum and seal the oxygen absorber bag (see photo above) after taking out what you need.

I can re-seal one of the oxygen absorber bags about four times... and if I've any remaining packets and the bag gets 'too short' to reseal, I'll put those remaining packets into a new bag and vacuum seal it!

Everyday Oxygen Absorber Uses You Didn’t Know You Needed

I use oxygen absorbers for dehydrated food storage for the following reasons:

- For dry foods - Oxygen absorbers prevent stale flavors, bugs, and rancidity in stored grains, beans, dried fruits, nuts, coffee, spices, and other dry goods.

- In Mylar bags - I use oxygen absorbers inside Mylar bags to remove oxygen when packaging bulk foods for long-term storage.

- Dehydrated foods - They help retain nutrients and prevent oxidation in dehydrated fruits, vegetables, and meats.

- Environmentally friendly - Oxygen absorbers reduce food waste by keeping home-preserved foods fresh for longer periods.

Handy Storage Reference Chart for Long-Term Food Safety

Layering matters! This quick chart lays out the sequence so you don’t miss a step when storing food.

| Layer | Container | What Goes Inside | O₂ Absorber | Desiccant | Seal Method | Notes |

|---|---|---|---|---|---|---|

| Primary | Vacuum-sealer bag | Dry food | 100cc | 5g | Vacuum seal | Wrap in cling film (abrasion guard) |

| Secondary | Mylar bag | 3–4 primary packs | 300cc | 20g | Heat-seal (no vacuum) | Barrier + light block; label contents & date. Text will now wrap properly instead of stretching wide. |

| Storage | Pantry/Shelf | Finished Mylar bundles | — | — | — | Cool, dark, dry; rotate oldest first |

Primary

Container: Vacuum-sealer bag

What Goes Inside: Dry food

O₂ Absorber: 100cc

Desiccant: 5g

Seal Method: Vacuum seal

Notes: Wrap in cling film (abrasion guard)

Secondary

Container: Mylar bag

What Goes Inside: 3–4 primary packs

O₂ Absorber: 300cc

Desiccant: 20g

Seal Method: Heat-seal (no vacuum)

Notes: Barrier + light block; label contents & date

Storage

Container: Pantry/Shelf

What Goes Inside: Finished Mylar bundles

Notes: Cool, dark, dry; rotate oldest first

FAQs: Oxygen Absorbers for Dehydrated Food

Below, you’ll find answers to the most common questions about using oxygen absorbers for dehydrated food, choosing the right size, and keeping your pantry stash safe for the long haul.

What are oxygen absorbers for dehydrated food?

What are oxygen absorbers for dehydrated food?

Oxygen absorbers are small packets filled with food-safe iron powder and salt. When placed in vacuum-sealer bags or jars, they remove oxygen from the air, which helps prevent mold, bugs, and rancidity — extending the shelf life of your dehydrated foods.

How do oxygen absorbers work?

How do oxygen absorbers work?

The iron inside reacts with oxygen through oxidation. As the iron rusts, it pulls oxygen out of the sealed container and reduces levels to nearly zero. This simple chemical reaction keeps your dried foods fresher for much longer.

Where can I buy oxygen absorbers?

Where can I buy oxygen absorbers?

Amazon is my go-to for fast delivery and trusted brands. Always check the freshness indicator pill inside the package — it should be pink. If it’s purple or blue, the absorbers are no longer good, and you should return them.

What foods need oxygen absorbers?

What foods need oxygen absorbers?

They’re best for low-moisture foods, such as:

- Dried beans, peas, lentils

- Rice, oats, wheat, barley

- Pasta, dehydrated potatoes

- Flour, sugar, salt

- Nuts, seeds

- Dried fruits and vegetables

- Jerky

- Coffee, tea, spices, baking ingredients

- Even dog and pet treats

Always make sure foods are fully dried and stored in airtight containers.

Can I reuse oxygen absorbers?

Can I reuse oxygen absorbers?

No. Once an oxygen absorber has fully reacted with oxygen, it cannot be recharged or reused. Always use a fresh packet.

How do I know if my oxygen absorbers are still good?

How do I know if my oxygen absorbers are still good?

Check the freshness pill in the bag. If it’s pink, the absorbers are still active. If it has turned purple or blue, they’ve been exposed to air and should be replaced.

What's the difference between oxygen absorbers and desiccant packs?

What's the difference between oxygen absorbers and desiccant packs?

Oxygen absorbers remove oxygen, while desiccant packs remove moisture. They do different jobs, but you can often use both together for maximum food protection.

Do oxygen absorbers make food safe to eat forever?

Do oxygen absorbers make food safe to eat forever?

No. They extend shelf life dramatically, but food still needs to be properly dehydrated, sealed airtight, and rotated over time. They don’t make food last forever.

Can oxygen absorbers touch food directly?

Can oxygen absorbers touch food directly?

Yes. Oxygen absorbers are food-safe and non-toxic, so it’s fine if they come into direct contact with your dehydrated foods inside jars or vacuum-sealed bags.

How many oxygen absorbers should I use in a jar or bag?

How many oxygen absorbers should I use in a jar or bag?

- Half-pint jar: 50cc

- Quart jar or vacuum-sealer bag: 100cc

- 5-gallon bucket: 2000cc

When in doubt, it’s always better to use a slightly larger absorber to ensure full protection.

Thanks for taking the time to learn about oxygen absorbers and why they’re essential for safe, long-term food storage. Once you start using them, you’ll see just how much fresher your dehydrated foods taste — whether it’s crunchy apple chips, hearty beans, or jerky for the trail.

Before you go, don’t miss grabbing my free 5 Dried Food Recipes You’ll Actually Love PDF (below). Inside, you’ll get step-by-step instructions for favorites like carrot soup, minestrone soup, split pea soup, spicy beef jerky, and even banana cinnamon rolls. They’re delicious, easy, and a great way to put your food storage to work!

Get 5 Dried Food Recipes You'll Actually Love

Here's where you can get your copy of our all new

5 Dried Food Recipes (That Actually Taste Great)

They're my all-time favorite easy dried food meals!

Get it here right now.

For Free!

Before You Go...

If you enjoyed this page, tap the ❤️ in the lower right-hand corner.

It saves this page to your Grow bookmarks so you can find it again later.

You’ll also see quick share buttons to copy the link, post to Facebook,

or save it straight to Pinterest.